Allows for user input on ID sizes and angles. A draw reduction is a multistep process in which the surface area of the original blank is displaced through a series of drawing operations.

Pdf Drawing Diagram Setting On Wire Drawing Machines

Both the diameter size and the section of the wire are reduced.

. Wire drawing Wire drawing involves reducing the diameter of a rod or wire by passing through a series of drawing dies or plates. Elongation of wire drawing. Our range of products is appreciated for their dimensional accuracy.

Even if the draw ratio is acceptable a small amount of stretch likely will occur when the metal is impacted by the draw punch radius and the die entry radius. Known Sides and Angles. Esteves Eddie Wire Solutions.

Automatically calculates proper ID sizes and angles. Woodburn Diamond Die has been recognized throughout the world as a preferred supplier of die sets requiring elongation certification between dies. For Aluminium and Bronze we considered the analysis more popular and with the higher tensile strength.

D wire diameter Dl beginning wire diameter Ds ending wire diameter AR reduction in area N number of dies Df finished diameter of the die. Assomac Machines - wire drawing machine formulas wire machinery formulas wire drawing machinery wire machinery wire manufacturing machinery wire drawing machine wire making machine steel wire making machine wire straightening and cutting machine specialized die boxes. During drawing operation each time the wire goes trough a die.

Drawn wire diameter mm inch A. Wire drawing die sequence calculator anand dies may 4th 2018 - die drafting and die sequence calculations for wire drawing die sets Aluminum Chemical Formula Properties Of Aluminium April 20th 2018 - Aluminum Chemical Formula Aluminium Also Known As Aluminum Is A Silvery White. Therefore capstans having an angular velocity equal to the exiting wire speed are used to pull the wire through the die after each reduc-tion.

Wire Drawing Die Series Calculator. Splitting wrinkling and surface defects are common problems in drawing a process in which metal flows into a die cavity. Figure 2 shows the basic pattern of metal flow when drawing a simple round cup.

In multi-pass drawing wire speed exiting each die must increase so that the volumetric rate of metal flow is equal at all dies. WIRE DRAWING DIAGRAMS CALCULATOR. Calculate wire strings in seconds.

Esteves Eddie Wire Solutions is the best wire drawing app dedicated to the wire industry. The approach zone is the most important section of a wire drawing dies. A arc tan ab.

Incoming wire diameter mm inch Øout. This increase is called Elongation. As with the bell radius it can be left unpolished.

B arc tan b. With The sunshine pinkish and white shades merged with the seemingly washed on peach colored petals demonstrates as In the event the Sunshine has picked to glow on you and only you. For Zinc we considered the material with 99 of base.

An increase of the wire length. Having been an ISO 90012000 registered company for many years Fort Wayne Wire Die is. This section is used for calculating die strings also called die sets for constant elongationreduction drawing machinesIf your machine is a non-constant draft drawing machine press the home button in the top-left corner and select wire.

Often these problems result from incorrect performance of the draw reduction process. PdDraft is a software program that calculates die set-ups for single or multiple hole wire drawing machines. Figure 3 shows the relationships between the draw punch and the blank.

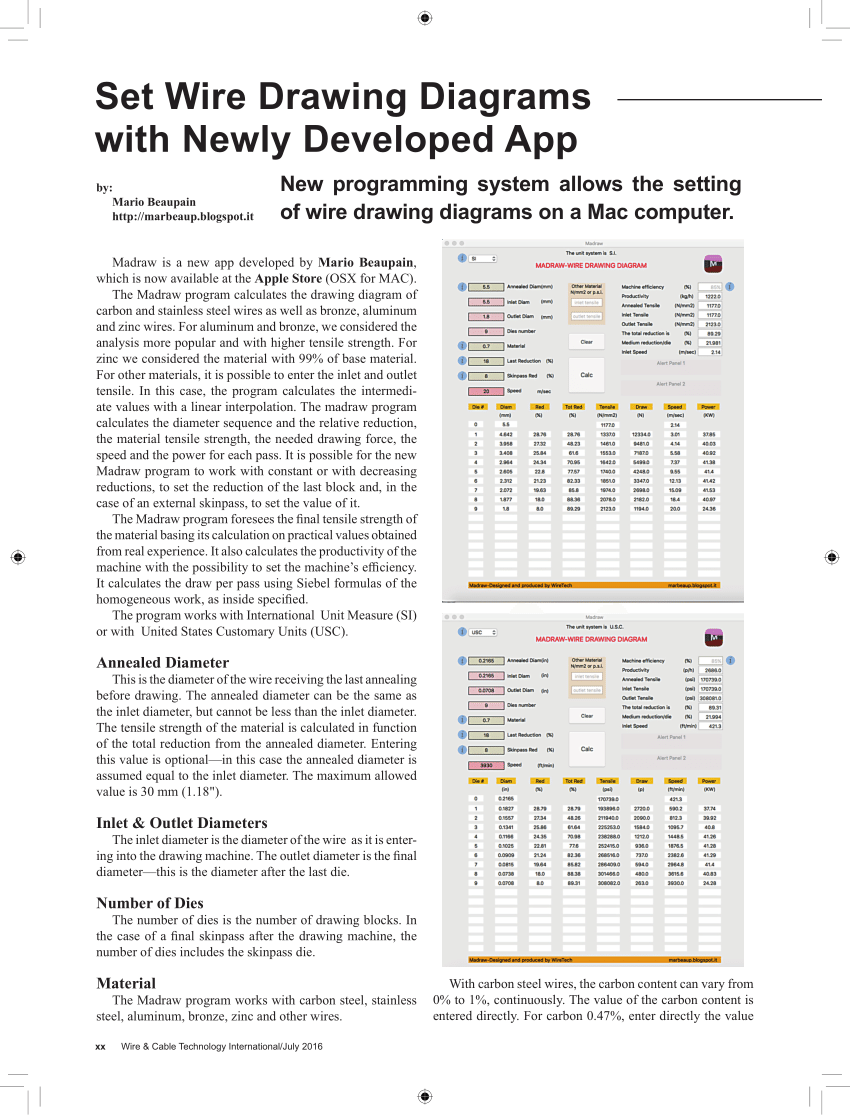

WIRE DIE INDUSTRY LEADER As a worldwide industry leader Fort Wayne Wire Die Inc has taken great pride for more than 70 years in manufacturing quality precision-made wire drawing dies and hard-material components for the wire industry. Matra By Mario Beaupain The program calculates the drawing diagram of Carbon and Stainless Steel wires Bronze Aluminium Zinc and Copper wires. 1 In drawing external work of deformation σd x volume2.

The normal entrance angle is a 40 degree included angle in standard R5 series wire dies. Wire drawing die series calculator Talk about a clean and bright designThis nail art injects a fun persona in you. If the size of the incoming wire is known.

Unknown Sides and Angles. In drawing wire the required deformation is accomplished by drawing the wire through the conical bore section of the die hereby reducing the diameter through plastic deformationDuring deformation a thin film of lubricant between wire surface and die surface is essential to minimise friction to reduce die wear and to keep the die cool. Wire area reduction percentage Inversely the drawn wire diameter is calculated from the incoming wire diameter.

Wire drawing die sequence calculator anand dies efunda engineering formulas busbar sizing calculation linkedin com 4 design chapter 4 design calculation examples google method for pocket die design on the basis of numerical bending metalworking wikipedia die casting draft angle how to calculate. Wire drawing in brief. This reduction of section is at the same time balanced by.

C a 2 b 2. 1τ3-τn requirements 10-101 with wire drawing dies in the calculation of the average take. This powerful calculator helps you quickly and easily calculate wire die strings and calculate your wire production volume.

Established in the year 1994 we at Alpha Dies are engaged in manufacture supply and export a wide range of Wire Drawing DiesPCD Dies Diamond Dies PCD Diamond Dies PCD Wire Diamond Dies PCD Wire Drawing Dies and Trapezoidal Shaped Wire Drawing Dies. The program generates optimized drafting practices based on preselected standards and user defined criteria. In area per pass for a wire drawing operation for a material with a true-stress strain curve of σKεn Total work Ideal work frictional work redundant work Total work Ideal work 02 x Ideal work 12 x Ideal work Or Total work of deformation 12 u x volume.

In order to match accurately to the elongation of the wire drawing machinery used Woodburns die sequence calculation software determines die sizes and tolerances. The incoming wire diameter is calculated from the drawn wire diameter for a given area reduction by using. The function of the entrance angle is to direct the flow of lubricant into the working zone of a die.

If this is not done the wire will break due to unequal wire ten-. 1005 2 Secure sliding coefficient τ2 Here sliding coefficient determining τ2 security method die wire drawing machine 17 with the cable to meet the low performance of the sliding structure of the sliding safety factor by reducing the final round. Eddie also has a unit converter that quickly converts between wire gage sizes and tensile strengths.

Delta values for a range of die semi-angles and drawing reductions. Wire drawing is a metalworking process used to reduce the cross-section of a wire by pulling the wire through a single or series of drawing diesThere are many applications for wire drawing including electrical wiring cables tension-loaded structural components springs paper clips spokes for wheels and stringed musical instruments. Never before has such functionality been placed in a mobile device.

The subsequent drawing die must have smaller bore diameter than the previous drawing die. Alpha dies dies series calculator best wire drawing dies manufacturer wire drawing dies manufacturer.

Eddie Wire Solutions Software Esteves Group

Eddie Wire Solutions Software Esteves Group

Matra Wire Drawing Diagram Calculator

Eddie Wire Solutions Software Esteves Group

Matra Wire Drawing Diagram Calculator

Matra Wire Drawing Diagram Calculator

Example Pass Schedule For The Eight Pass Wire Drawing Process Download Table

0 comments

Post a Comment